Food and Drink Sector

Our extensive work in the food and drink sector over the last 20 years has seen us work on everything from fizzy drinks flavours to chocolate mixing plants. Our engineers and project managers specialise in helping companies where our knowledge of (bio)chemical engineering, hygienic design and process safety can come to the fore. We have significant experience around all core unit operations for the food and beverage sector, including:

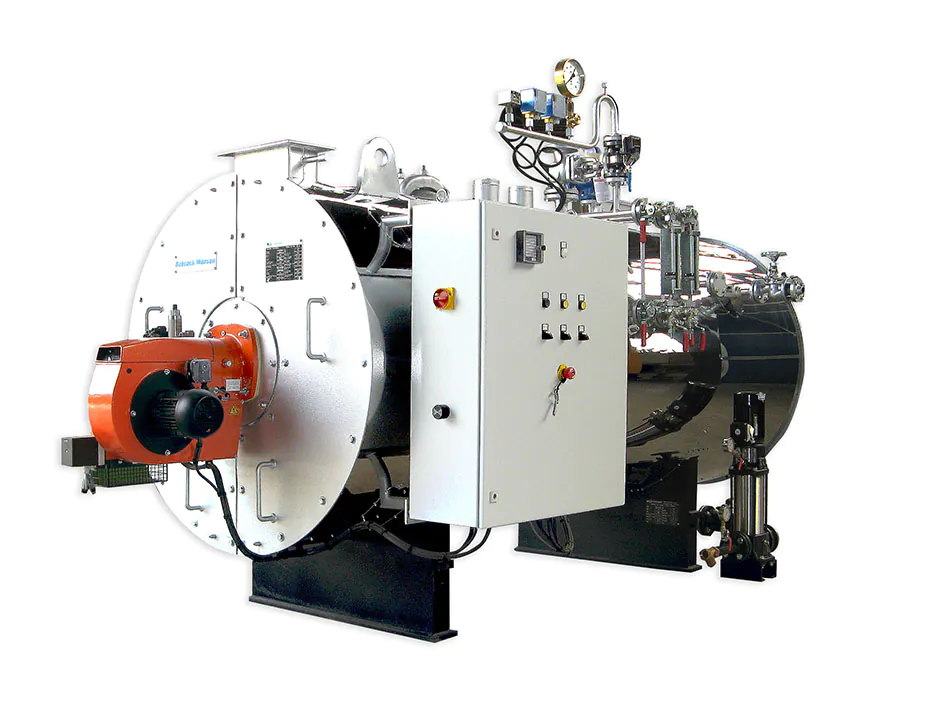

- Heat transfer

- Mixing

- Drying

We understand that food and drink industry in particular has stringent rules and regulations regarding process safety and compliance. We have vast experience in helping process engineers meet complex guidance and legislation so they can focus on production.

Contact Our Team